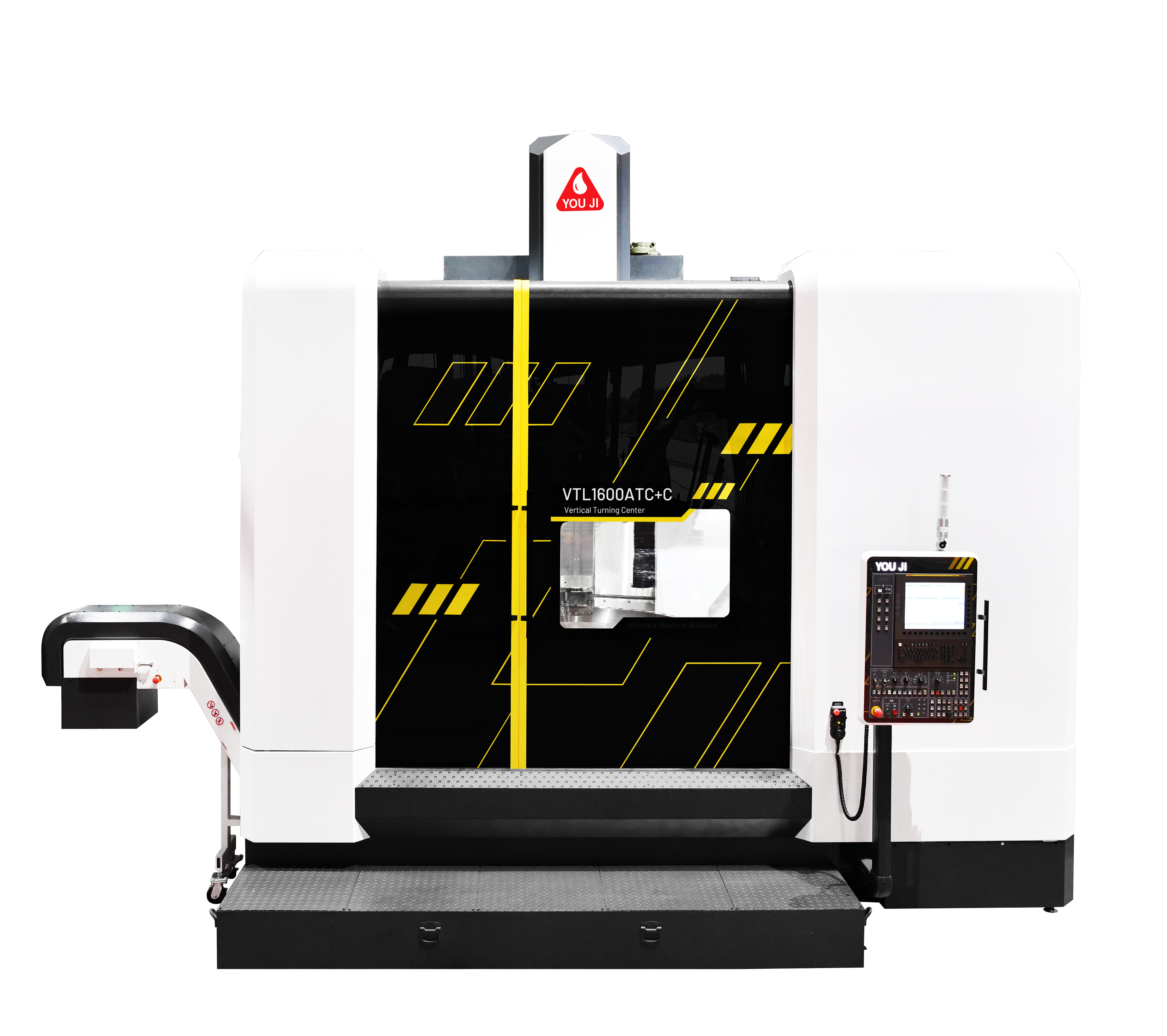

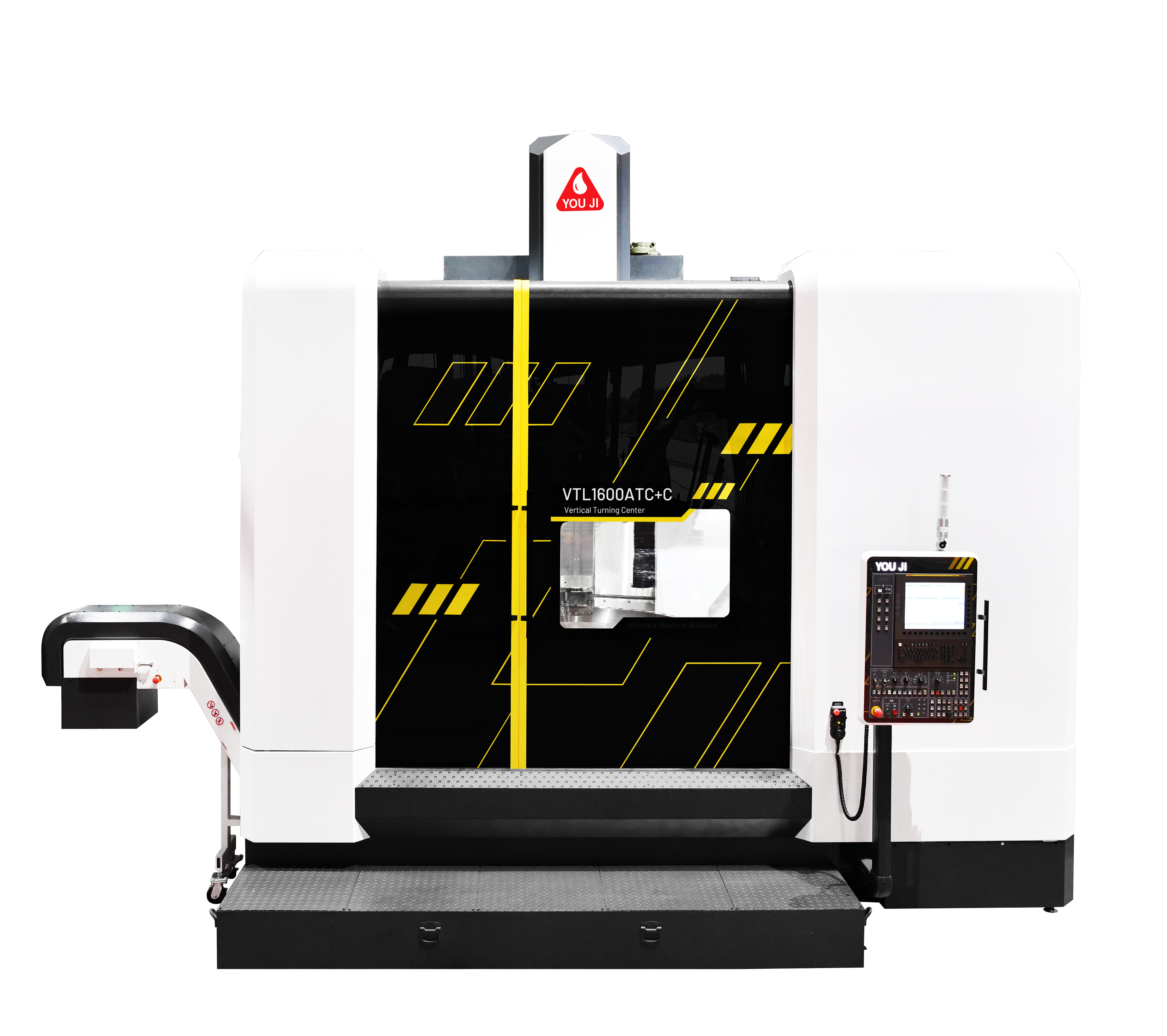

Big Iron, Tight Space – DAY 1 – You Ji VTL1600ATC+C Install:

TDT Machine Tools has today begun the installation of another You Ji VTL1600ATC+C in the north west. The VTL1600ATC+C is a large heavy duty vertical turning centre with automatic tool changer and live tooling capability, and it’s the latest in a growing number of heavy-duty machine tool projects delivered by TDT across the UK.

We’ll be documenting the installation process over the next couple of weeks — from first lifts to training — this blog will be updated regularly with photos and progress as the machine takes shape on site.

Four Containers, Two Days, One Goal

The VTL is arriving in four separate containers over a two-day period, with components ranging from the main bed and column to the ATC, control panel, and guarding systems.

Day 1 saw the arrival of the first three containers. The operation began early, with the crane and unloading team ready to go on site for an 8am start. Working with the customer’s in-house team and site support, our engineers began unloading, unpacking, and positioning the base — the largest and heaviest single component of the machine.

You Ji unloading base from container

The machine spends six weeks being tossed around on the open seas so packing at the factory when the machine is decommissioned is important.

You Ji VTL1600ATC+C unpacking TDT CNC

You Ji VTL Column

Base Placement: Zero Margin for Error

By 10am, the machine base was lowered into position — a job made significantly more difficult by the layout of the facility. The machine will sit on a lower-level section of the workshop, sunken relative to the rest of the factory floor. While it’s not technically a pit install, the restricted overhead clearance and floor access has added considerable complexity to this job.

You Ji VTL1600ATC+C install positioning TDT CNC

This is exactly the kind of situation where our customers benefit from TDT’s experience. We’ve managed numerous large-scale installations across the UK, often in workshops that weren’t originally designed with this scale of machine in mind. Our team came prepared with a full install plan tailored to the site’s limitations, allowing the first stage of the job to run smoothly and safely. There are many visits with a ‘tape measure’ to check every step of the preparation for delivery and install.

This first lift — and the entire early build phase — has been carried out with the support of Midland Machine Movers, who are working closely with TDT engineers on site. Their role in safely unloading, positioning, and assembling the major structural elements — base, column, crossrail and ram — is essential for their ‘lifting and shifting’ expertise and also ensures everyone is fully compliant with site safety. Having a trusted partner for heavy rigging gives us the confidence to safely install almost anything anywhere.

This is exactly the kind of situation where our customers benefit from TDT’s experience. We’ve managed numerous large-scale installations across the UK, often in workshops that weren’t originally designed with this scale of machine in mind. Our team came prepared with a full install plan tailored to the site’s limitations, allowing the first stage of the job to run smoothly and safely.

Planning Ahead: Tight Space, Tight Timeline

There’s minimal margin for error on this install — the physical layout of the building means components need to be unpacked and lifted in a specific sequence, and we have to keep the install area clear of obstruction throughout.

Everything is planned to the minute of detail even down to what order we would like the containers delivered.

The build will include:

-

Assembly of base, column and crossrail and ram.

-

Turret and ATC system integration.

-

C-axis and live tooling checks.

-

Full guarding, chip conveyor, and control installation

-

Power-up, geometry checks, and commissioning

- finally training and test cuts.

We’ll also be performing laser alignment and accuracy verification before handover to the customer’s production team.

Why TDT? Big Machines, Handled Properly

We’ve developed a solid reputation for installing and supporting machines that most companies would class as “challenging” — either because of their size, site limitations, or both. That’s why we’re increasingly referred to by our own team and customers as #thebigmachinecompany.

From heavy-duty bed mills to large VTLs and double column machining centres, we’ve managed installations in nuclear, aerospace, mining, and heavy general engineering sectors — often in tight, high-pressure environments.

Check Back for Daily Updates

This blog will be updated daily with new photos and progress reports as the installation continues. If you’re planning a large-capacity machine install, want to see how complex jobs are handled on site, or are just curious about what it takes to land and build a VTL of this size — follow along.

This is how the machine will look in just a couple of weeks.

You Ji VTL1600ATC+C-ALL NEW-A-S

If you’re considering investing in large machine tools, get in touch — we’ll show you how we make the complex manageable.

#thebigmachinecompany

#YouJiVTL1600ATC

#TDTMachineTools