© TDT Machine Tools Limited

All Rights Reserved | Design by eSterling

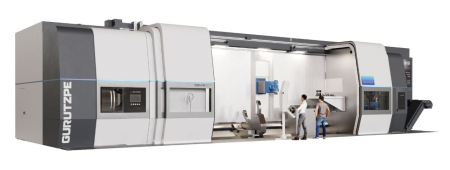

GS Series Turn-Mill lathes

GURUTZPE GS Series – Slant-Bed Turnmill Machines

The GURUTZPE GS Series represents a class of slant-bed turnmill centres engineered for heavy, precision turning and milling in a single machine. Combining the strength of a slanted base with robust construction and versatile machining capability, the GS Series is ideal for high-accuracy production in energy, aerospace, oil & gas, rail, defence, and large-component subcontracting industries.

What is a Slant-Bed Turnmill?

A slant-bed turnmill combines the best features of a horizontal lathe and a machining centre. Its inclined bed design provides superior rigidity, easy chip flow, and excellent access — allowing heavy turning and milling operations to be completed in a single setup. This reduces cycle times, improves accuracy, and eliminates costly part handling between machines.

Engineered for Heavy Machining & Precision

The GS Series is built around a stiff slant-bed frame that enhances structural stability and support under load:

-

Inclined bed configuration for improved chip evacuation and rigidity

-

Large swing diameters and generous distance between centers

-

Precision-ground guideways for consistent positioning accuracy

-

Heavy-duty spindle options engineered for high torque and sustained cutting loads

-

Built to withstand large cuts and demanding cycle profiles

This design delivers the power, stability, and precision needed to machine large, complex parts confidently and repeatably.

Turnmill Capability — One Machine, Multiple Processes

The core advantage of the GS Series is its ability to perform multiple machining operations without part transfer:

-

Turning and facing

-

CNC milling on multiple axes

-

Drilling, boring and contouring

-

C-Axis interpolation (where applicable) for advanced profiling

-

Optional live tooling and toolchanger packages

By combining these processes, GS machines minimise setups and improve throughput — a major advantage in medium-to-high-volume production.

Applications That Benefit Most

The GURUTZPE GS Series excels with large, heavy, and precision-critical components such as:

-

Shafts, spindles, and rotors

-

Large housings, flanges, and rings

-

Axles and wheelsets for rail

-

Valve bodies, pump casings and housings

-

Defence and aerospace structural parts

If your workshop relies on multi-process efficiency and heavy duty reliability, the GS Series delivers consistent performance.

Why the GS Series Stands Out

✔ Designed for simultaneous turning and milling in one setup

✔ Slant-bed rigidity reduces vibration and improves surface finish

✔ Heavy-duty spindles and drives for high torque and deep cuts

✔ Flexible tooling options for complex geometries

✔ Ideal for high-value, large-batch production environments

Talk to Us About Your GS Series Solution

The GS Series can be configured to your exact production needs — from spindle options and tooling packages to automation and probing systems. Get in touch with us to discuss specifications, competitive pricing, and application optimisation.

Enquire about GS Series Turn-Mill lathes

If you have any questions about this product, please fill out the form below and we will get back to you as soon as possible.