© TDT Machine Tools Limited

All Rights Reserved | Design by eSterling

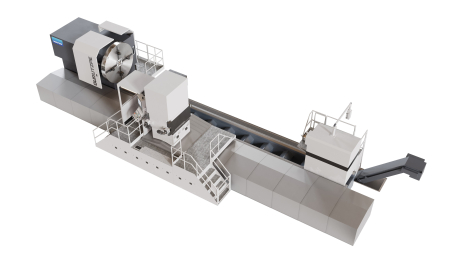

GH Series Hydrostatic flat-bed lathes

GURUTZPE GH Series – Hydrostatic CNC Horizontal Lathes

The GURUTZPE GH Series delivers next-level performance for heavy-duty precision turning. Built with advanced hydrostatic guiding technology and robust structural design, these horizontal lathes are engineered for machining large, complex components with exceptional accuracy, rigidity, and longevity — ideal for energy, aerospace, oil & gas, rail, and industrial sectors.

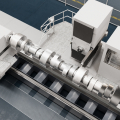

Hydrostatic Technology for Ultimate Precision

At the heart of the GH Series is a hydrostatic “pump-per-pocket” guiding system that supports both longitudinal and transverse axes. By creating a fluid film between sliding surfaces, this system delivers:

-

Unmatched rigidity & damping for heavy cuts

-

Ultra-smooth, vibration-free motion

-

Exceptional positioning accuracy

-

Near-zero friction and virtually infinite guide life

-

Real-world durability under high loads

Hydrostatic guidance is widely regarded as the premium solution for large-capacity CNC lathes — where precision and reliability cannot be compromised.

Built for Massive Parts & High Tonnes

The GH Series can be tailored to your application with two primary configurations:

➤ GHH – Single-Bed Hydrostatic Lathe

-

Ideal for components up to Ø 3,000 mm

-

Capacity up to 90 tonnes between centres

-

Single cast-iron bed with hydrostatic guide carriage

-

Perfect for precision turning on long shafts and heavy parts

➤ GHD – Double-Bed Hydrostatic Lathe

-

Designed for the largest workpieces up to Ø 4,000 mm

-

Capacity up to 200 tonnes between centres

-

Double cast-iron base for even greater stiffness and stability

-

Best choice for extremely heavy, high-precision machining tasks

Both variants deliver the rugged performance needed in demanding industrial environments.

Versatile Machining & Smart Features

The GH Series isn’t just a lathe — it’s a fully adaptable machining platform:

-

Multi-operation capability (turning, milling, grinding, internal machining)

-

Automated tooling and head change options for productivity

-

Internal turning anti-vibration bars up to Ø400 mm

-

Advanced sensorisation and Industry 4.0 real-time monitoring

-

Multiple steady rests for optimal workpiece support

-

Integration with ATC / AHC packages for flexible machining workflows

Applications That Demand Precision & Power

These hydrostatic horizontal lathes excel across heavy industrial sectors:

-

Power generation and turbine components

-

Oil & gas rotating parts

-

Railway wheelset and axle machining

-

Defence and aerospace structural parts

-

Steelworks and heavy industrial equipment

If the job demands high tonnage machining with tight tolerances, the GH Series delivers.

Why GURUTZPE GH Series Is Best-In-Class

✔ Hydrostatic guiding for unrivalled stability

✔ High damping, minimal wear and long service life

✔ Modular and customisable to fit your production needs

✔ Large swing and weight capacity for oversized workpieces

✔ Smart features for Industry 4.0 and predictive maintenance

Talk to Us About Your Machining Requirements

Whether you’re tackling heavy turning, complex multi-operation parts, or looking to integrate advanced automation, the GH Series can be configured to match your exact needs. Contact us today to discuss specifications, customisation options, and pricing.

Enquire about GH Series Hydrostatic flat-bed lathes

If you have any questions about this product, please fill out the form below and we will get back to you as soon as possible.